Excerpt

Cross-Disciplinary Medical Advances with Neuroengineering

CHALLENGES SPUR DEVELOPMENT OF UNIQUE REHABILITATIVE AND THERAPEUTIC INTERVENTIONS.

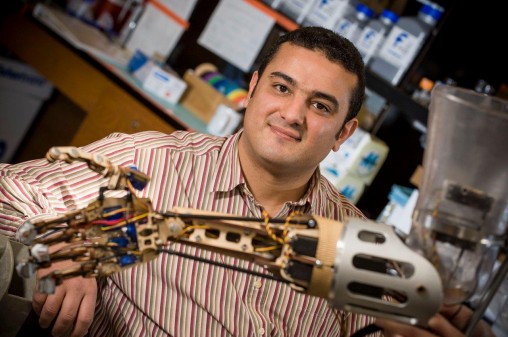

NEUROPROSTHETICS

One area in which neuroengineering is making significant progress is prosthetics. Advances in design and mechanics have produced state-of-the-art limb prosthetics that realistically mimic physiological movements. Such artificial substitutes are also equipped with kinetic and pressure sensors that give real-time information on whether the prosthesis is opening or closing, the speed of the motion, whether a prosthetic hand has touched an object, and the extent of grip firmness.

However, this mechanical feedback is not returned through the amputee’s nerves, nor does it reproduce naturally modulated motor control, proprioception, or sensation. Thus, neuroengineering aims to enable prosthetic sensors and motors to communicate, respectively, with the residual sensory and motor nerves in the amputee’s stump, so that the amputee can use natural neural processes to drive the prosthesis. This is expected to make the prosthesis move and feel more like a natural limb.

Many engineering and neuroscience challenges must be addressed to achieve successful communication between the prosthesis and the nervous system. On the engineering side, for instance, the design of implanted electrodes to record nerve signals and communicate them to the prosthesis control unit will be challenging. These electrodes must be small enough to fit around nerves, yet maintain stable contact for stimulation or recording; support the measurement of small-amplitude neural signals; and have durable leads that resist damage during movement.

Transmission between electrodes and the prosthesis control unit should be wireless to minimize connection breakdowns but support fast transmission speeds for real-time performance. The battery must have a large charge capacity for long operation hours and be small and lightweight to maintain prosthesis agility. To fit several in a prosthetic hand, the motors also need to be small and lightweight yet still provide precise movement, accurate performance, superior mechanical operation, ease of maintenance, and durability.

Read the entire story at pulse.embs.org

Wright State alum Lindsay Aitchison fulfills childhood space-agency dream

Wright State alum Lindsay Aitchison fulfills childhood space-agency dream  Wright State business professor, alumnus honored by regional technology organizations

Wright State business professor, alumnus honored by regional technology organizations  Wright State University Foundation awards 11 Students First Fund projects

Wright State University Foundation awards 11 Students First Fund projects  Gov. DeWine reappoints Board Treasurer Beth Ferris and names student Ella Vaught to Wright State Board of Trustees

Gov. DeWine reappoints Board Treasurer Beth Ferris and names student Ella Vaught to Wright State Board of Trustees  Joe Gruenberg’s 40-Year support for Wright State celebrated with Honorary Alumnus Award

Joe Gruenberg’s 40-Year support for Wright State celebrated with Honorary Alumnus Award