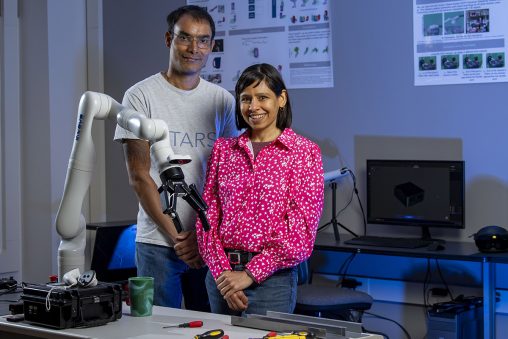

Wright State faculty members Sean Banerjee and Natasha Banerjee are leading a $3 million National Science Foundation project that will use advanced technologies to help recycling plants turn scrap metal into new products while training workers and students in high-tech manufacturing. (Photos by Erin Pence)

Two Wright State University faculty members are leading a $2.999 million National Science Foundation project that could transform how scrap metal is recycled into new products — and position Wright State as a national leader in what they call “recyclofacturing.”

Natasha Banerjee, Ph.D., and Sean Banerjee, Ph.D., associate professors in the Department of Computer Science and Engineering and LexisNexis endowed co-chairs for advanced data science and engineering, are leading the multi-university research project. The collaboration includes Santa Clara University, Chapman University, the University of Lynchburg and Clarkson University, with Wright State serving as the lead institution.

The couple, who joined Wright State in 2024, originally applied for the prestigious Future Manufacturing Research Grant as faculty members at Clarkson University in New York.

It is the second-largest National Science Foundation research award Wright State has ever received.

Their goal is to keep more manufacturing in the United States by equipping recycling facilities with advanced technologies — such as artificial intelligence, extended reality and human-robot collaboration — so workers can turn usable metal parts into new products rather than shipping scrap overseas.

“When a washer or refrigerator breaks down, we take it to a metal recycling facility, where traditionally they’re shredded on site into scrap that gets shipped overseas for processing,” Natasha Banerjee said. “What we propose is that if large portions of those are intact and usable, workers onsite at the recycling plant can make small products from them. Why not fabricate onsite, keeping manufacturing in the U.S. and in the local community?”

The approach could revive the kind of small fabrication shops once common across the United States, but with a modern, high-tech update.

Recycling plant employees would be trained as “recyclofacturers,” using AI-driven design tools, virtual reality headsets for step-by-step guidance and collaborative robots to assist with assembly and welding.

The Banerjees hope to create a system where a customer could request a custom item — such as a pencil holder — that would be designed, cut and assembled locally from recycled materials.

“We’re driving new research in using technology that’s Gen Z-friendly to assist recycling plant workers in refabrication,” Natasha said.

The project also includes an education and workforce development component. Community courses will introduce people to the new tools and techniques, while Wright State students will gain hands-on experience through research assistant positions starting in the spring of 2026.

The Banerjees added that they are aware that workers are worried about being replaced by robots. But the researchers will focus “on the ways robots can help people so that people can maintain their autonomy,” Natasha said. “If humans and robots can collaborate, there’ll be a successful outcome.”

Sean Banerjee noted that this year, only Virginia Tech and Michigan State — along with Wright State — received National Science Foundation Future Manufacturing Research Grants focused on cyber-technologies. “That puts us on the same playing field as those two universities,” he said.

The recyclofacturing project will train recycling plant employees to utilize AI-driven design tools, virtual reality headsets, and collaborative robots to fabricate new products from scrap metal.

“Being part of such a large NSF grant is an excellent opportunity for Santa Clara University to collaborate with Wright State and our other partner institutions to shape the future of manufacturing in the U.S.,” said Maria Kyrarini, Ph.D., assistant professor of electrical and computer engineering at Santa Clara. “This is an interdisciplinary award that brings together computer scientists, engineers, sociologists, economists and stakeholders.”

As part of the project, the Wright State team will begin acquiring high-tech equipment in September, including a robotic weld-training system, a robotic arm, a high-performance GPU computer and augmented reality and virtual reality systems.

“This grant brings novel technologies to Wright State,” Natasha Banerjee said. “Wright State will be the face of pushing new technologies for manufacturing.”

Milling around

Milling around  Wright State recognizes Nursing Professor Kim Ringo for advancing international student success

Wright State recognizes Nursing Professor Kim Ringo for advancing international student success  Wright State honors graduating students for distinguished doctoral dissertations

Wright State honors graduating students for distinguished doctoral dissertations  Top 10 Newsroom videos of 2025

Top 10 Newsroom videos of 2025  Museum-quality replica of historic Hawthorn Hill donated to Wright State

Museum-quality replica of historic Hawthorn Hill donated to Wright State