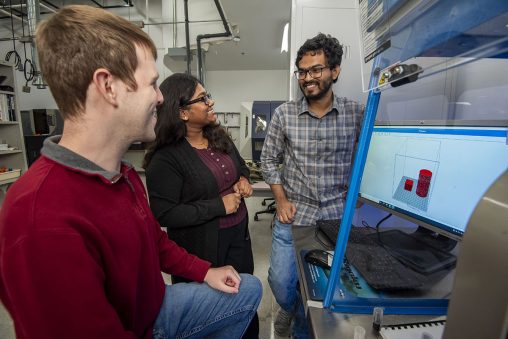

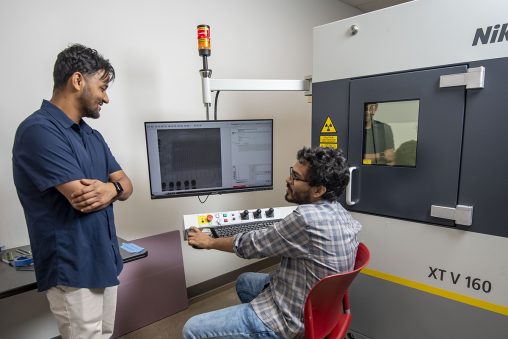

Wright State’s College of Engineering and Computer Science and Lake Campus secured grants from the Ohio Department of Higher Education to provide additional opportunities for students to train on the latest electric vehicle and advanced manufacturing technologies. (Photos by Erin Pence)

Wright State University engineering students will gain more hands-on experience with the latest electric vehicle and advanced manufacturing technologies, thanks to two state grants for new high-tech training equipment.

The Ohio Department of Higher Education awarded Wright State a total of $579,000 through its Regionally Aligned Priorities in Delivering Skills (RAPIDS) program to strengthen education and training opportunities and workforce development efforts in the state.

Wright State received $399,000 from the Super RAPIDS Automotive and Advanced Mobility program to provide equipment for training in battery manufacturing and testing, vehicle electronics, secured connectivity and automotive manufacturing.

Another $180,000 grant will provide modern manufacturing tools, including 3D printers, advanced software, cameras for industrial automation and other technology, to prepare students for in-demand careers.

The funding will enhance classroom learning on Wright State’s Dayton and Lake campuses, benefiting both traditional and nontraditional students, as well as local industry workers seeking skills training.

The main objective is to train students who make and maintain electric vehicles (EV) and other advanced manufacturing areas.

“The market share of EV is going up,” said Ahsan Mian, Ph.D., professor of mechanical engineering and director of research and outreach in the College of Engineering and Computer Science. “We need to train our students for that market. We need to be prepared.”

The RAPIDS grants will also allow Wright State’s Lake Campus to continue updating the equipment on which its students train.

At the Lake Campus, new technology will include a LiDAR unit (Light Detection and Ranging) that measures and maps distances in 3D, and an industrial vision device that interprets information from robotic sensors on a production line and electric vehicle simulation equipment to teach how EV systems work and how batteries are charged.

The equipment will be used to educate and train students majoring in manufacturing technology and in mechanical engineering. It will also be available to train nontraditional and non-credit students and local workers.

“We’re a hub for our local manufacturers and businesses, having available training close by. Our goal is to meet the community’s needs,” said Tammy Eilerman, director of the Workforce Development and Business Enterprise Center at the Lake Campus. “The number one concern is to attract a talented workforce. We need to prepare our students for the workforce now and in the future.”

The state funding will enhance classroom learning on Wright State’s Dayton and Lake campuses, benefiting both traditional and nontraditional students, as well as local industry workers seeking skills training.

While the focus is on electric vehicles, Mian also sees opportunities in emerging fields such as autonomous vehicles.

“Unmanned, driverless vehicles, they’re coming for sure,” he said. “Some of this equipment will be helpful for training students in driverless cars, for their repair and servicing and for engineering, designing and testing driverless vehicles.”

Mian added, “We are thankful to the ODHE for their continuous support in acquiring new equipment to provide training. ODHE is appreciative of what we do.”

Milling around

Milling around  Wright State recognizes Nursing Professor Kim Ringo for advancing international student success

Wright State recognizes Nursing Professor Kim Ringo for advancing international student success  Wright State honors graduating students for distinguished doctoral dissertations

Wright State honors graduating students for distinguished doctoral dissertations  Top 10 Newsroom videos of 2025

Top 10 Newsroom videos of 2025  Museum-quality replica of historic Hawthorn Hill donated to Wright State

Museum-quality replica of historic Hawthorn Hill donated to Wright State