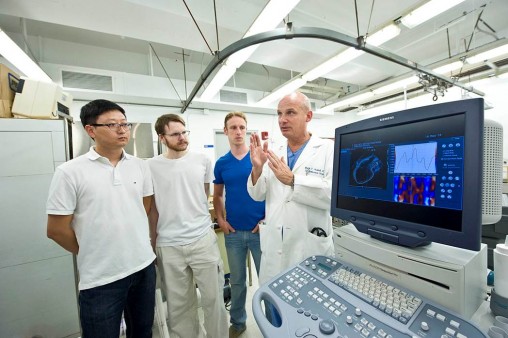

Dr. Mark Anstadt (right) explains the images displayed on an echo machine with students (from left) Yirong Zhou, Ben Schmitt and Kevin Carnahan, in a lab where students study on a revolutionary heart pump.

In a basement lab at the Medical Sciences building — the beat goes on.

A revolutionary heart pump there is providing a rare learning opportunity for Wright State University students. The pump is attached to a mock human circulatory system — a student-designed plumbing marvel of clear plastic piping that simulates the flow of life-giving blood.

The mock circulatory system, called the “mock,” is supported by hundreds of thousands of dollars’ worth of sophisticated cardiosurgical equipment.

“They’re using the same tools we’re using clinically,” said Mark Anstadt, M.D., a cardiothoracic surgeon and Wright State professor who runs the lab. “A lot of students don’t understand what they’re getting their hands on. If they master this, they can step into the clinical world. It’s invaluable.”

At the center of the lab experience is the Anstadt Cup, a life-saving heart pump invented in the early 1960s by Anstadt’s father, George L. Anstadt. The cup is inserted into the body of a patient through an incision and is vacuum attached around the heart, squeezing the blood out and then drawing it back in.

The device is ideal for quick application during heart failure because it can maintain heart function and blood flow until the patient can be stabilized. And it doesn’t come into contact with the blood, which makes the use of anti-clotting medicines unnecessary and reduces the risk of stroke and infection.

Dr. Mark Anstadt working with the mock circulatory system that simulates the flow of life-giving blood.

“If somebody’s dying, you can put it in very quickly and you can bring people back,” Anstadt said. “What we’re focusing on in the lab is trying to build a drive system that’s not so complex and more user friendly. We would like to get it into the environment where it can help humans.”

The students who have worked in the lab over the years have come from the Boonshoft School of Medicine, the College of Engineering and Computer Science and the Biomedical Sciences Ph.D. program.

David Reynolds, Ph.D., assistant chair for biomedical engineering, has supplied the lab with many of his students and holds senior advanced biotransport classes there.

Kevin Carnahan, a former Wright State biomedical engineering student now in medical school at Ohio University, helped design the latest version of the circulatory mock and incorporated it into a lab for Reynolds.

“The unique part were the ventricles themselves and how those attach to the rest of the mock. That was probably the hardest part,” Carnahan said.

The students also designed a mock heart made of silicon rubber by creating a mold from a computer model and a 3-D printer. The mock heart is used as part of the mock circulatory system.

“Nobody had done that before,” Reynolds said.

Anstadt, who was a cardiothoracic surgery research fellow at Duke University for 10 years, said the mock takes the testing of the heart pump to a higher level.

For example, a $250,000 echo machine that is used to visualize the inner workings of the heart has been hooked up to the mock. It enables Anstadt and the students to analyze heart strain, learn how the material of the pump performs and fine-tune the power levels.

“That echo machine is the same thing we use in open-heart surgery,” said Anstadt. “That’s probably the most exciting thing we’re doing in the lab — looking at a heart that’s being pumped by this device because we can look at heart function and failure and how this helps that along.”

Anstadt said the lab is a great place for medical students to learn more about engineering and for biomedical engineering students to learn more about physiology.

“The things we have in the lab transcend more than one discipline,” he said. “I think they help you launch into the field you want to go.”

Wright State faculty member Damaris Serrano wins Panamanian literary award

Wright State faculty member Damaris Serrano wins Panamanian literary award  Wright State grad Hannah Beachler earns Oscar nomination for production design on ‘Sinners’

Wright State grad Hannah Beachler earns Oscar nomination for production design on ‘Sinners’  Wright State alum Emily Romigh builds on a family legacy in education

Wright State alum Emily Romigh builds on a family legacy in education  Wright State receives $3 million grant to strengthen civic literacy and engagement across Southwest Ohio

Wright State receives $3 million grant to strengthen civic literacy and engagement across Southwest Ohio  Fitness Center renovation brings new equipment and excitement to Wright State’s Campus Recreation

Fitness Center renovation brings new equipment and excitement to Wright State’s Campus Recreation