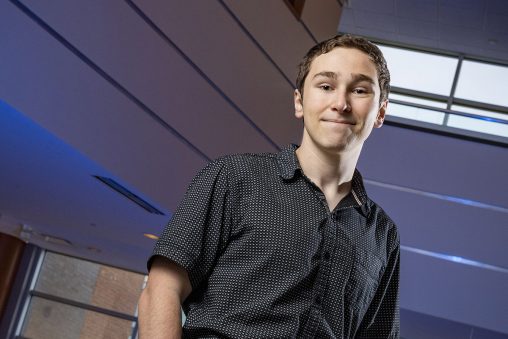

Alex Vehre, who is majoring in mechanical engineering, develops non-destructive tests for ceramic materials as part of his internship with the Air Force Research Laboratory.

When he’s not playing the violin or learning Arabic, Wright State University mechanical engineering major Alex Vehre works to help the Air Force develop non-destructive tests for ceramic materials.

It’s part of Vehre’s internship with the Air Force Research Laboratory at Wright-Patterson Air Force Base. AFRL is a scientific research organization dedicated to the discovery and development of aerospace warfighting technologies. It controls the Air Force’s science and technology research budget.

Vehre began his internship at AFRL in November 2019. He has worked to help develop non-destructive testing capabilities of ceramic matrix composites. The composites consist of ceramic fibers embedded in a ceramic matrix. They are less likely to crack or fracture than conventional ceramics and are used in aircraft and military vehicles.

However, they are expensive, difficult to see through and challenging to test without the materials being damaged or destroyed in the process. So developing non-destructive testing methods is important.

Vehre recently gave a poster presentation at AFRL on air-coupled ultrasound inspections of the composites. Conventional ultrasonic tests are conducted using water or gel as a transmitting medium, but air-coupled ultrasound has advantages.

“However, air is a particularly difficult couplant to work with. So we are addressing that challenge,” said Vehre. “They liked my presentation.”

Vehre grew up in the western Ohio city of Greenville. His mother is a physician who works at a local clinic, and his father recently retired as director of the Greenville Public Library.

Vehre started playing the violin in second grade. He has since played in the Dayton Philharmonic Youth Orchestra and in pit orchestra productions.

“The violin has always been a passion of mine,” he said. “While I haven’t done as many musicals because of COVID, I have still been playing at my church and it’s been a wonderful experience.”

Vehre’s strength in math and love of the STEM fields drew him to engineering.

“I love how everything works together, and I love efficiency,” he said.

Vehre said the highlight of his time at Wright State has been the people with which he has gotten to network and the career opportunities he has had.

He said Wright State’s mechanical engineering program has given him a very solid foundation.

“I learned a lot of theory that I used at work in class,” he said. “The internship is a materials engineering job, but my classes have really has helped me learn the base information to expand out and learn new things for the job.”

Vehre said the biggest challenge of his internship was getting up to speed with leading techniques in the field. But he said he has gained a lot of specialized knowledge and experience in ultrasonic testing and thermography, which uses infrared cameras to produce images.

After graduating in the spring, Vehre would like to pursue a Ph.D. in aerospace engineering, with a focus on propulsion and non-destructive testing.

Vehre’s Wright State experience is not all engineering. It includes language learning.

“I’m a huge enthusiast of studying the structures and cultures associated with different languages,” he said. “My favorites right now are Spanish, German, Chinese, Japanese and Arabic. I took an Arabic class this semester. It’s been wonderful.”

Milling around

Milling around  Wright State recognizes Nursing Professor Kim Ringo for advancing international student success

Wright State recognizes Nursing Professor Kim Ringo for advancing international student success  Wright State honors graduating students for distinguished doctoral dissertations

Wright State honors graduating students for distinguished doctoral dissertations  Top 10 Newsroom videos of 2025

Top 10 Newsroom videos of 2025  Museum-quality replica of historic Hawthorn Hill donated to Wright State

Museum-quality replica of historic Hawthorn Hill donated to Wright State